Why Screen Print?

[vc_row][vc_column width=”1/2″][ultimate_heading main_heading=”Reasons Screen Printing still matters in 2017/18″ main_heading_font_size=”desktop:30px;”][/ultimate_heading][vc_column_text css_animation=”fadeIn”]

Digital technology including the big World Wide web has transformed the graphics arts industry.

Digital artists and designers have a whole new world of opportunities including all the varied printing specialities, the horizons opened up a massive advantage for small entrepreneurs to start up small and rapidly expanding printing companies.

Although all this technology and future advances help the graphic design arts industry we shouldn’t take for granted the pure art form of traditional printing methods such as silk screen printing.

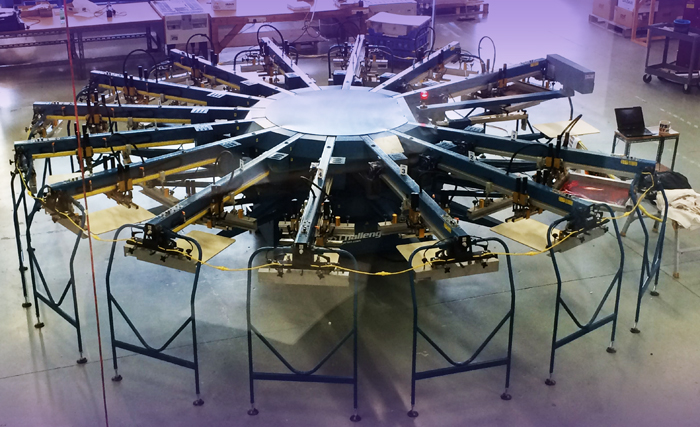

There have been some great advances in printing methods but silk screen printing is still the most traditional printing method that hasn’t really changed. The machinery has changed rapidly in the industry, large run carousel presses and efficient dyer machinery. This hasn’t changed the process though in any shape or form, it’s just made the screen printing much more efficient. Below are reasons why you should use silk screen printing for your branding or marketing garments/products.

Cost Efficient for large volumes

Screen printing is more cost-efficient than any digital form of printing. If you have a large volume print run screen printing can replicate your images thousand’s of times on the latest carousel printing presses. Screen printing comes into it’s own when it’s high volume runs replicating thousand’s of imagery.

Versatile Materials

The Screen printing method accommodates a varied range of materials to print onto. T-shirts, hoodies, aprons, plastics and vinyls, glass, metals and much more. Screen printing also offers a Pantone® specific system, this means branded specific Pantones® can be matched with inks to match logos or brand ID’s. Vivid colour’s are also available for darker garments, so screen printing really does have a great variety in terms of printing materials. Sizes don’t need to be specific, the press only has a maximum in width so size variation is extremely versatile.

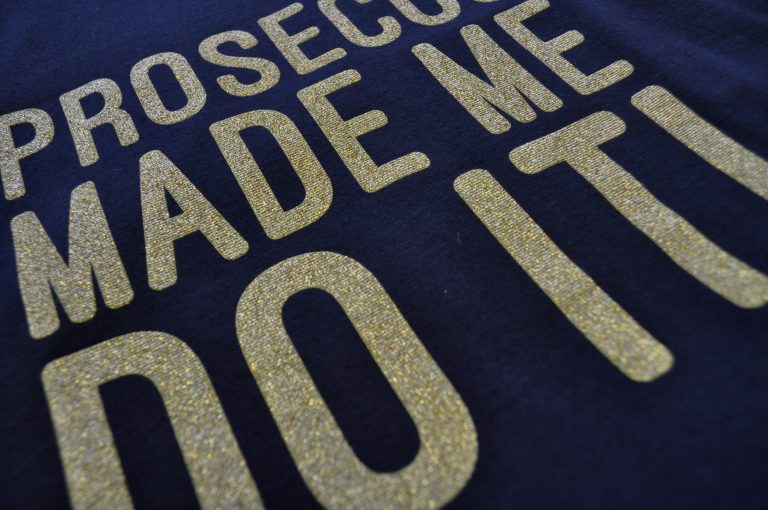

Unique output and inks

Screen printing techniques haven’t really changed over the decades, the only change is the inks we use to manipulate the garment materials. Screen printing inks can be applied in many different options, Discharge, Glitter & Shimmer, Plastisol, Foils, UV & Solvent inks and water based, Puff, Metallic, Neon, Rainbow.

High quality

Screen printed garments are much more durable than other methods of printing, this makes them last longer and withstand wear and tear. As apposed to heat transfer printing screen printing can last much longer and be washed many times without losing the high quality. Screen printed garments/t-shirts are better screen printed if they need to last longer and be durable. It would be a good process if your business staff need uniforms to wear everyday and need them to last longer.

Screen printing ink additives can be added to the mix and make the ink resistant to UV rays, chemical and moisture, this will allow the printing last much longer.

So why choose Screen printing?

Versatile, cost effective, durable and high quality, these are just some of the reasons to use this method above any of the digital methods around today. [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”2096″ img_size=”full” css_animation=”fadeIn”][vc_single_image image=”1968″ img_size=”full” css_animation=”fadeIn”][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row]