Why digital transfer printing

Uses for Transfer printing

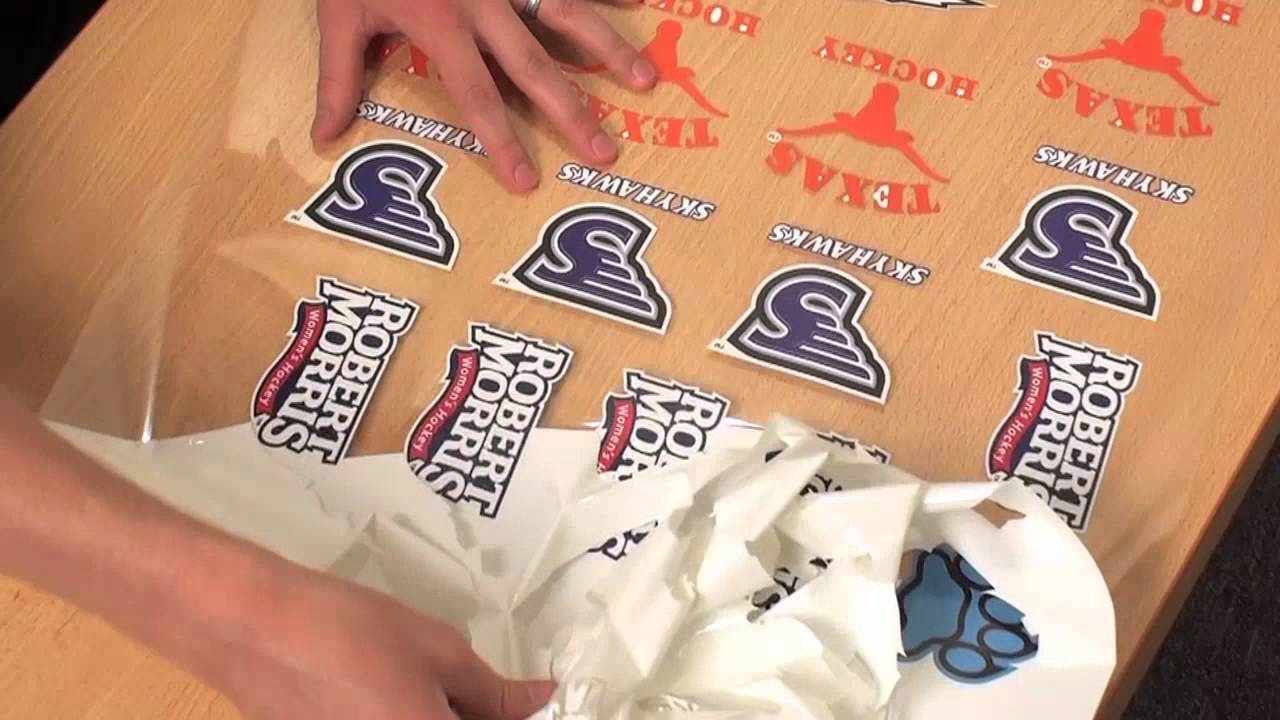

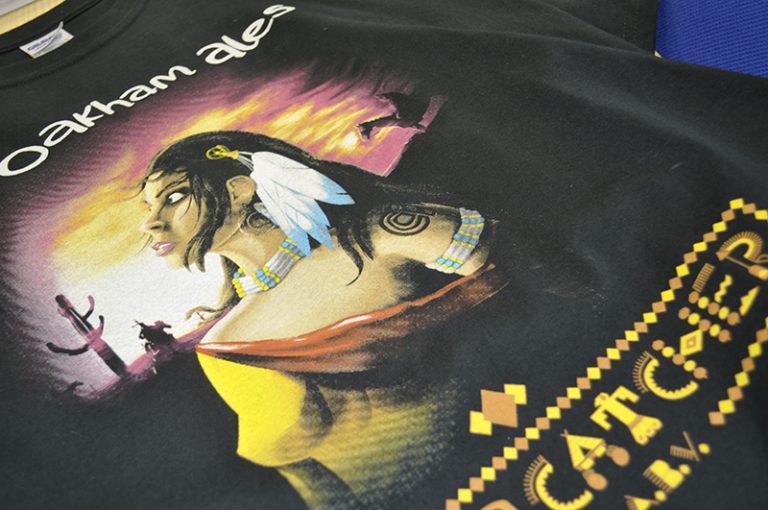

Transfer printing is a process we use where we print your design onto a vinyl transfer material. Once we have printed your artwork onto the material it is then heat pressed onto your specific garment. it is a great option for printing high colour artwork quickly and very cost effectively. The print quality is great for short runs such as promotional products or quick handout products. Colours acheived are extremely vibrant.

Why use our Transfer Printing service?

Transfer printing is best suited to short printed garments, is is available to light or dark colours. On dark gaments we use a thick material, on white we use a transparent materail so we use the white of the garment/s to full affect. The colours are printed use a CMYK process on top of the white substrate. so we ask for all artwork supplied is hires 300dpi is actual size. Depending on the garment is how good or effective the printed product will be finished. Our trained staff will make sure that the correct print process is used for your supplied garment/s.

Pros and Cons of Transfer Printing:

Pros:

- Ideal for very low quantity T-Shirt runs and clothing which features the same design

- High-quality printing replications

- Full-colour CMYK designs

- Very quick to set up and print

- Low cost involved

Cons:

- Not suited to large runs

- No Pantone ® colour matching

- Garment can feel heavier

- Transfers can feel thick (depending on design)

The transfer machine cuts out your design leaving less vinyl, so you don’t end up with a big plastic vinyl transfer over your garment. This makes the garment feel less heavy and more breathable. The artwork must be supplied full size at 300dpi, our printed will only print he quality in relation to the supplied artwork. The last thing we want is our customer unhappy at the quality of the print if the artwork is low resolution.